THE PROBLEM

Energy Assurance received an inquiry from a company about testing a proprietary algorithm for controlling a battery management system.

Their primary concern was that the algorithm was a sensitive IP, and they needed to protect it.

In addition to proper test equipment and capabilities, the company sought a partner who could help them keep the algorithms and all data related to the tests 100% in-house. This would include hiding it from the Energy Assurance team as a total insulation from potential exposure to the market.

THE PROPOSED SOLUTION

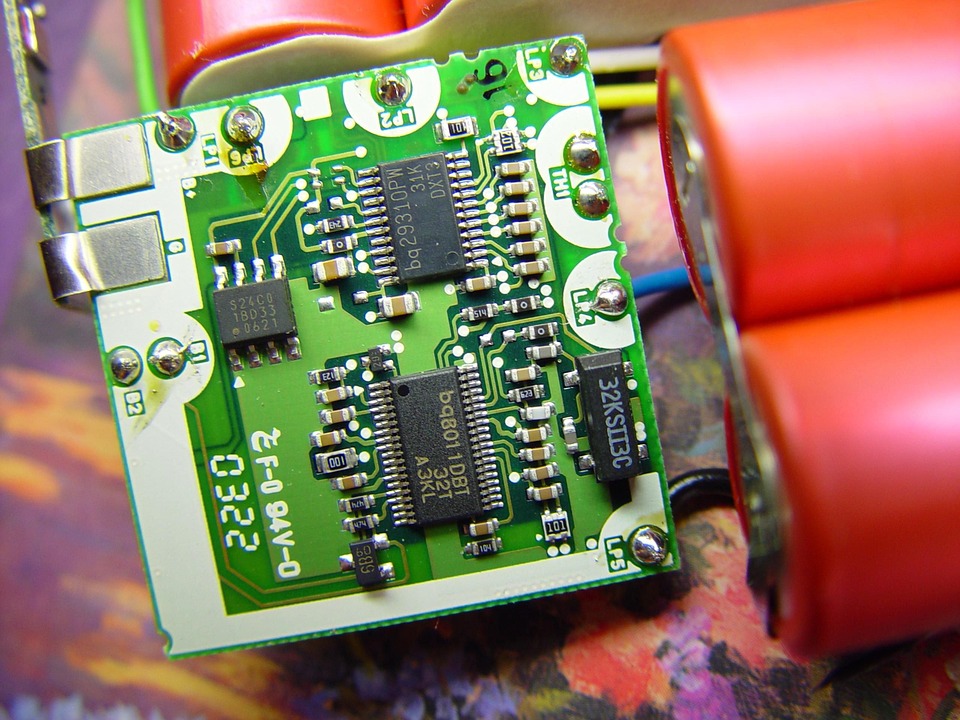

Our team rose to the challenge. After consultation with the customer, the proposed solution was unorthodox, but innovative. We would give them the ability to access and control the battery cyclers within our network with the help of Raspberry Pi technology. The Raspberry Pis would come loaded with the customer’s proprietary algorithm. Using these specially prepared devices, the customer could connect with our on-site MACCOR battery cyclers and make appropriate adjustments with only limited interfacing from Energy Assurance. Since our team would be minimally involved in the system data (merely as facilitators and equipment providers), they could fully protect their IP.

WHY ENERGY ASSURANCE?

The biggest hurdle for the customer was locating a testing partner who would allow this sort of unconventional access to their lab, network, and battery cyclers — and who was prepared to put in the time and effort to make it work.

Many testing labs would have balked due to logistical questions and equipment risks. We were all in. Energy Assurance committed to developing a process for the customer to tunnel into our network and talk to their Raspberry Pi fleet in a secure fashion. The Pis would then write data to control the MACCOR battery cyclers directly.

THE CHALLENGES

We were able to overcome this hurdle by working with MACCOR to make sure that nothing the Raspberry Pi units were doing could override those internal safeties.

This was easier said than done. Achieving these goals took close collaboration between Energy Assurance, the customer, and MACCOR. We worked together to design an effective and secure process that minimized risks to both the sensitive IP and our facility.

The threat of thermal runaway was real. We wanted to ensure that this process wouldn’t override the built-in safeties on our MACCOR cyclers, charging batteries beyond their limits and potentially sending them into thermal runaway. Such an accident could ignite a dangerous fire, damaging the equipment and our facility.

THE RESULTS

The mission was a total success.

The mission was a total success.

The customer was highly satisfied with the final process for accessing our network and cyclers remotely through the Raspberry Pis. We received praise for being a devoted partner that gave a lot of attention to solving a highly bespoke request.

Our companies have continued to work together on multiple programs since this first project. The Raspberry Pi test, more than a year ago, proved to be only the first in a line of solutions that Energy Assurance has delivered with consistent satisfaction.

TAKEAWAYS

In the end, this project led to the creation of a unique and convenient new capability. Energy Assurance now has a proven method for an outside party to protect their proprietary technology within a third-party test facility — and without any personnel external to their company viewing it.

There’s also the benefit of a third-party perspective and access to advanced third-party equipment. In this case, the customer was able to leverage our battery cyclers from MACCOR, a market-leading provider of the finest test equipment available.

This new process offers not only a useful field test, but a way for our customers to leverage the world-class capabilities and equipment of America’s leading independent battery testing lab — their own way — without compromising their IP.

Energy Assurance undertakes diverse battery testing projects for customers across the aerospace, military, medical, and consumer electronics sectors. Our facilities feature over 3,500 cycler channels and a wide range of other electrical, mechanical, and visual evaluation capabilities for custom cell or battery screening operations.

Contact us at information@energyassurance.com or call 404-954-2054 to discuss your needs!